My shopping cart

Your cart is currently empty.

Continue Shopping

Getting the rough opening size wrong for your bifold door can turn a simple installation into a costly nightmare. Whether you’re working on walk in closets, pantries, or room dividers, Understanding common bifold door sizes is crucial, as proper rough opening sizing is the foundation of any successful bifold door installation. The difference between smooth installation and frustrating adjustments often comes down to precise measurements and understanding the relationship between actual door sizes and the space they require. Getting the right size bifold door depends on how accurately the opening is measured.

In this comprehensive guide, you’ll learn exactly how to size a rough bifold door opening, from understanding basic requirements to avoiding common pitfalls that can derail your project. We’ll cover standard bifold door sizes, step-by-step measuring techniques, and the critical calculations that ensure your door panels fit perfectly and operate smoothly for years to come. Before selecting a door, it’s essential to have the opening properly measured to guarantee the best fit and function.

Bifold doors are a smart solution for maximizing space and adding style to any room. Designed with multiple hinged panels, bifold doors fold and slide along a track within the door frame, making them ideal for areas where traditional swinging doors would take up too much space. Whether you’re outfitting closets, pantries, or dividing a room, bifold doors offer a wide selection of sizes and configurations to suit your needs. Their ability to open wide while taking up minimal floor space makes them a favorite for both homeowners and builders. Understanding the different bifold door sizes and how they fit within your door frame is essential for a smooth installation and a perfect fit, ensuring your new doors operate effortlessly and enhance the look of your space.

The rough opening is the framed, unfinished space in a wall where your bifold door will be installed. This opening must be larger than the actual door size to accommodate the door frame, hardware, and installation adjustments. The opening for a bifold should be slightly larger than the door itself to ensure proper fit, smooth operation, and easy hardware installation. Think of it as providing breathing room for your bifold doors to function properly without binding or misalignment.

Proper rough opening sizing ensures smooth bifold door operation and prevents the binding issues that plague poorly planned installations. When the opening is too tight, door panels struggle to fold and unfold freely. When it’s too loose, you’ll face gaps, poor sealing, and potential structural problems that compromise both function and appearance. The actual size of the openings must be carefully considered to avoid these operational issues.

Industry standards have evolved to address these challenges with proven formulas. Standard rough openings are typically 2 inches wider and 2.5 inches taller than the nominal size door dimensions. This allowance accommodates jamb boards, top track hardware, and the fitting tolerance needed for professional results. For example, a standard door measuring 36 inches wide by 80 inches tall requires a rough opening of 38 inches wide by 82.5 inches tall. However, actual measurements can vary slightly due to construction or manufacturer differences.

To ensure accurate measurements, don’t forget to use a tape measure, as t he extra space serves multiple purposes beyond just hardware accommodation. It provides adjustment room for walls that aren’t perfectly plumb or square, allows for different flooring thicknesses, and ensures adequate clearance for the door panels to operate without obstruction. Without this space, even minor construction variances can cause major installation headaches.

Always consult the manufacturer's instructions to ensure your rough opening meets all specific requirements for your bifold door.

Understanding common bifold door sizes and their corresponding rough opening requirements forms the backbone of successful sizing. The most frequently used residential bifold doors come in standard widths and heights that correspond to typical room and closet openings. Common dimensions for bifold doors include a range of standard sizes designed to fit most residential spaces, but custom sizing is also available for non-standard openings.

For width calculations, the math is straightforward but critical and is based on the standard size for bifold doors:

These measurements account for the door frame thickness and necessary installation clearances. The 2-inch additional width provides space for the jamb boards on both sides while allowing for minor adjustments during installation.

Height requirements follow a similar pattern with slightly more allowance:

The additional 2.5 inches in height accommodates the top track system, provides proper clearance above the door panels, and allows for the standard 3/4-inch undercut at the bottom. This undercut ensures the door clears finished flooring materials like carpet, tile, or hardwood without binding. Standard doors are designed to fit these rough opening measurements, making installation more predictable and reducing the risk of improper fit.

When working with custom size bifold doors or larger openings, these ratios typically remain consistent, though it’s essential to verify manufacturer guidelines for specific products. Some specialty doors or heavy-duty systems may require different rough opening dimensions to accommodate reinforced hardware or unique mounting requirements.

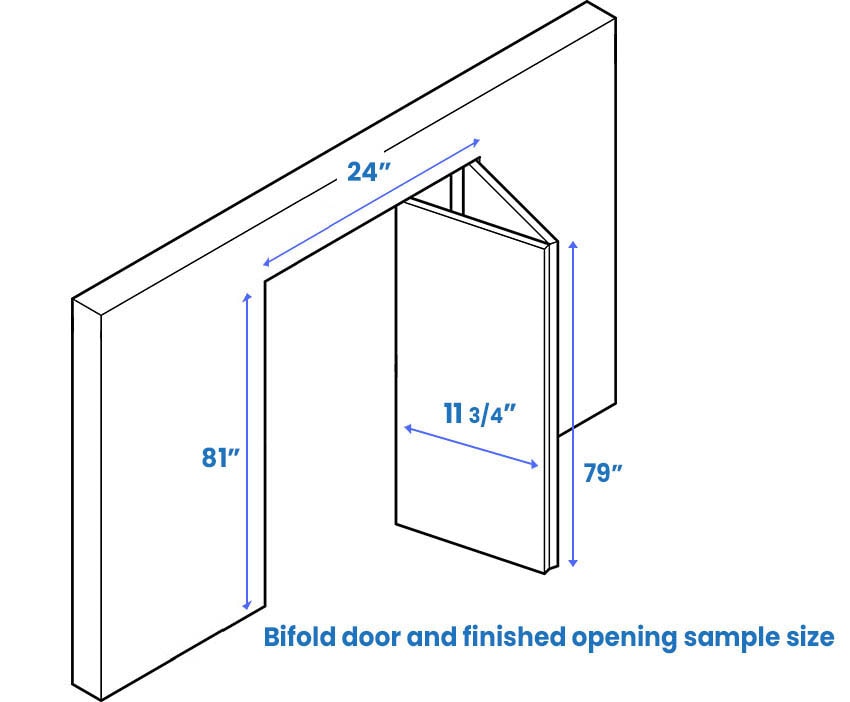

When shopping for bifold doors, it’s important to know the difference between nominal and actual sizes. The nominal size is the standard, labeled measurement you’ll see on packaging or in catalogs—such as 36” x 80”—but the actual size of the bifold door is typically a bit smaller. This difference allows for the necessary space to accommodate hinges, hardware, and tracks during installation. For example, a bifold door with a nominal size of 36” x 80” will usually have an actual size of about 35½” x 79”. This slight reduction in actual sizes ensures a proper fit within the opening and makes installation easier, preventing the door from binding or sticking. Always check the actual size of the door before finalizing your rough opening measurements to guarantee a seamless fit and smooth operation.

Accurate measurement forms the foundation of proper bifold door sizing, and the process requires both the right tools and systematic approach. Start by gathering essential equipment: a reliable tape measure, a quality carpenter’s level, a sharp pencil for marking reference points, and a calculator for double-checking your arithmetic.

Before taking any measurements, verify that your opening is properly framed and ready for assessment. The walls should be plumb, the header should be level, and any electrical or plumbing work should be completed. This preparation prevents measurement errors caused by incomplete framing or temporary supports.

Begin the measuring process by checking the opening at multiple points to account for construction irregularities that can affect door fit. Measure the width at the top, middle, and bottom of the opening, recording all three measurements. Similarly, measure the height at the left side, center, and right side of the opening. These three measurements for each dimension reveal any variations in the framing that could impact installation.

Always record the smallest measurement from your three readings, as this represents the limiting dimension that will determine your door size. Even if two measurements match and one is smaller, use the smallest dimension to ensure proper fit throughout the entire opening.

Understanding the relationship between nominal and actual sizes is crucial for accurate rough opening calculations. Bifold doors are typically sold by their nominal size, but the actual door dimensions are slightly smaller to allow for operation clearances.

Measure the width of each individual bifold door panel if you have the doors on-site. For two panels making up a standard bifold door, each panel typically measures slightly less than half the total nominal width. For instance, a 36-inch nominal bifold door usually consists of two panels measuring approximately 17 3/4 inches each, totaling 35 1/2 inches in actual width.

When working with four panels for larger openings, the same principle applies - the combined actual width of all panels will be less than the nominal size. This difference becomes the starting point for your rough opening calculations, ensuring you account for the real space requirements rather than just the advertised dimensions.

Door height measurements should include the full panel height from top to bottom. Standard heights like 80 inches typically translate to actual panel heights of 79 inches, providing the necessary undercut for floor clearance. Measure carefully and verify these dimensions against manufacturer specifications before proceeding with rough opening calculations.

To determine the required rough opening width, add 2 inches to the combined actual width of the door panels. This calculation provides space for the door frame installation and necessary adjustment tolerances. The 2-inch allowance accommodates standard jamb thickness on both sides of the opening while providing fitting tolerance for professional installation.

For example, if your door panels have a total width of 35 1/2 inches, your rough opening width should measure 37 1/2 inches. However, since most construction follows standard increments, you might round up to 38 inches to match common lumber dimensions and provide additional adjustment room.

When working with single track systems or specialty hardware, verify that the standard 2-inch allowance adequately accommodates your specific installation requirements. Some heavy-duty or commercial-grade bifold systems may require additional width to properly install reinforced tracks or mounting hardware.

Consider the wall construction and finish materials when finalizing your width calculations. If you’re installing in a wall with thick drywall, tile, or other finish materials, ensure your rough opening accounts for these elements without compromising the door operation or appearance.

Height calculations require adding 2.5 inches to the actual door panel height to accommodate top track installation and floor clearance requirements. This allowance ensures proper installation of the track system while maintaining adequate clearance for door operation.

The 2.5-inch addition breaks down into specific allowances: approximately 1.5 inches for top track and mounting hardware, 3/4 inch for floor clearance (undercut), and a small buffer for adjustment and installation tolerances. This combination ensures your bifold doors operate smoothly without binding on the floor or hitting the header.

Account for flooring thickness when calculating final height requirements. If you’re installing carpet, tile, hardwood, or other finished flooring after the door installation, subtract the flooring thickness from your floor clearance to maintain proper door operation. For example, if you’re planning 1/2-inch hardwood flooring, reduce your undercut calculation accordingly.

Measure the height carefully at multiple points to identify any irregularities in the floor or header that might affect door operation. A level floor and header are crucial for proper bifold door function, so address any significant variations before finalizing your rough opening height.

Fitting tolerance is a key consideration when measuring for bifold doors. It refers to the extra space you need to ensure the doors can open and close smoothly without rubbing or sticking. To achieve a perfect fit and smooth installation, it’s recommended to subtract about half an inch from your opening measurements to allow for this fitting tolerance. This extra space is especially important in older homes or where walls may not be perfectly straight. When ordering custom bifold doors, be sure to specify whether your measurements already include fitting tolerance, as this will help avoid installation issues and ensure your doors operate as intended. Properly accounting for fitting tolerance is the difference between a door that glides open effortlessly and one that causes frustration every time you use it.

Before proceeding with door installation, verify that your rough opening is square and level to prevent operational problems and ensure professional results. An opening that’s out of square will cause binding, uneven gaps, and premature wear on hardware components.

To check if your opening is square, measure diagonally from corner to corner in both directions across the opening. Equal diagonal measurements confirm that your opening is square and ready for door installation. If the diagonal measurements differ by more than 1/4 inch, adjust the framing before proceeding with door installation.

Use a quality level to verify both vertical and horizontal alignment of your opening. Check that both side jambs are plumb (perfectly vertical) and that the header and sill are level (perfectly horizontal). Even minor deviations from level can cause significant problems with door operation and appearance.

Address any squareness or level issues before installing your bifold doors. Small adjustments to framing are much easier and less expensive than trying to compensate for these problems after door installation. Take the time to get the rough opening right, and your door installation will proceed smoothly with professional results.

Bifold doors are available in a range of sizes and configurations to fit different spaces and needs. Standard bifold door widths typically range from 18” to 36”, with standard heights of 80” and 96” to match most interior door openings. For larger openings, such as those found in walk in closets or wide room dividers, 4DR bifold doors are a great option. These larger doors come in widths of 48”, 60”, and 72”, featuring two sets of bifold panels on a single track for smooth operation across wider spaces. Choosing the right bifold door size and configuration ensures that your doors not only fit the opening but also function properly and look great in your space. Understanding these options helps you select the right bifold door for any application, from compact closets to expansive walk-in spaces.

Selecting the right bifold door starts with careful measurement and consideration of your specific needs. Begin by measuring the rough opening’s width and height, taking into account the door frame, jamb boards, and any corner bead that may affect the final fit. Decide whether a single track or bi fold configuration best suits your space, and consider the number of panels needed for the opening. The material and style of the bifold door—such as wood, glass, or metal—should complement your room’s design and intended use. Don’t forget to factor in the type of hardware required for smooth installation and operation. By thoroughly measuring and considering all these elements, you’ll be able to choose the right bifold door size and configuration, ensuring a perfect fit, easy installation, and years of reliable performance in your home.

Several frequent errors can compromise bifold door installation success, and understanding these pitfalls helps ensure your project succeeds. Learning from common mistakes saves time, money, and frustration during installation.

One of the most frequent errors involves forgetting to account for door frame thickness when measuring. The jamb boards add approximately 1.5 inches to the total width requirement, and failing to include this dimension results in an opening that’s too narrow for proper installation. Always add the full 2-inch width allowance to accommodate frame installation and fitting tolerance.

Not considering flooring changes that affect door clearance represents another common oversight. If you plan to install new flooring after door installation, account for the flooring thickness in your height calculations. Carpet, tile, hardwood, and their associated underlayments can significantly reduce floor clearance and cause binding issues.

Measuring only at one point instead of multiple locations fails to identify wall irregularities that affect door fit. Construction variances are normal, and measuring at three points for both width and height reveals these variations before they become installation problems. Always use the smallest measurement to ensure adequate clearance throughout the opening.

Confusing nominal door sizes with actual door dimensions leads to rough opening calculations that don’t match reality. Remember that bifold doors, like other interior doors, have actual sizes that differ from their nominal designations. Base your calculations on actual door dimensions rather than the size labels.

Failing to verify manufacturer’s instructions before finalizing rough opening dimensions can result in installations that don’t meet specific product requirements. While industry standards provide reliable guidelines, some specialty doors or hardware systems have unique requirements that supersede standard calculations.

Different bifold door configurations require specific considerations that may affect rough opening sizing beyond standard calculations. Understanding these variations ensures proper sizing regardless of your specific door type or application.

Two-panel bifold doors represent the most common configuration and typically follow standard rough opening calculations without modification. These doors work well for standard closets, pantries, and smaller room openings where the simple folding action provides adequate access.

Four-panel bifold doors, commonly used for larger openings or room dividers, may require additional width considerations beyond the standard 2-inch allowance. These systems often benefit from a center post or reinforced framing for stability, which can affect the total opening width required. Consult manufacturer guidelines for specific requirements when working with four-panel systems.

Custom-sized bifold doors require careful coordination with manufacturer specifications to ensure proper rough opening sizing. Non-standard sizes may have different hardware requirements or clearance needs that affect the standard calculation formulas. Work closely with your door supplier to verify exact requirements for custom installations.

Heavy or reinforced doors may need larger rough openings to accommodate heavy-duty hardware or additional structural support. Glass panel bifold doors, solid wood doors, or commercial-grade systems often require modified sizing calculations to ensure proper installation and operation.

Specialty mounting systems, such as ceiling-mounted tracks or soft-close mechanisms, may also affect rough opening requirements. These systems can require additional height clearance or modified framing to accommodate their installation requirements.

Once you’ve calculated and verified your rough opening dimensions, several preparation steps ensure your installation proceeds smoothly and professionally. Proper preparation prevents delays and complications during the actual door installation process.

Remove all construction debris, protruding nails, and obstructions from the rough opening before beginning installation. Clean surfaces allow for proper hardware mounting and prevent interference with door operation. Pay particular attention to the header area where track mounting requires a clean, solid surface.

Install any necessary blocking or reinforcement for track mounting before door installation. Heavy doors or ceiling-mounted systems may require additional framing support beyond standard wall construction. Install this blocking during the rough opening preparation phase rather than trying to add it after doors are in place.

Verify that electrical wiring, plumbing, or HVAC systems within the wall cavity won’t interfere with door installation or operation. Reroute or protect any utilities that could be damaged during installation or that might interfere with door hardware mounting.

Check for and install corner bead or other wall finishing materials that could affect door clearances. Wall finishes can reduce your effective opening size, so account for these materials in your final measurements and make adjustments as necessary—especially if you are choosing the right doors for vaulted ceilings.

Document all final measurements and any special installation notes for reference during door ordering and installation. Take photos of the prepared opening and keep measurement records easily accessible. These references prevent confusion and ensure consistency if multiple people work on the project.

Double check all calculations one final time before ordering doors or beginning installation. Verify that your rough opening dimensions properly accommodate your specific door size, hardware requirements, and installation tolerances. This final verification step prevents costly mistakes and ensures project success.

Learning how to size a rough bifold door properly sets the foundation for successful installations that operate smoothly and look professional. The process requires attention to detail, careful measurement, and understanding of the relationship between door dimensions and opening requirements.

Remember that the right bifold door installation starts with understanding nominal and actual sizes to get the opening size correct from the beginning. Take time to measure carefully, account for all variables, and verify your calculations before proceeding. The extra effort invested in proper sizing pays dividends in installation ease and long-term door performance.

Whether you’re working on walk in closets, room dividers, or any other bifold door application, following these guidelines ensures your project succeeds. When considering different door sizes, measure carefully, allow for proper clearances, and don’t rush the preparation process - your perfect fit depends on getting these fundamentals right.